Production performance overview

Production performance is the ability of the factory to meet planned production demand. However, in today's market environment, when products are rarely made to stock and most manufacturers have become made-to-order businesses or job shops, not knowing the type and mix of work ahead of them, the business has to rely on the correctness of its budget and hourly rates it reflects, by constantly monitoring actual utilisation of its work centres. Based on work centre utilisation data, ZOOMFAB calculates actual earnings and profits and compares them with the budget.

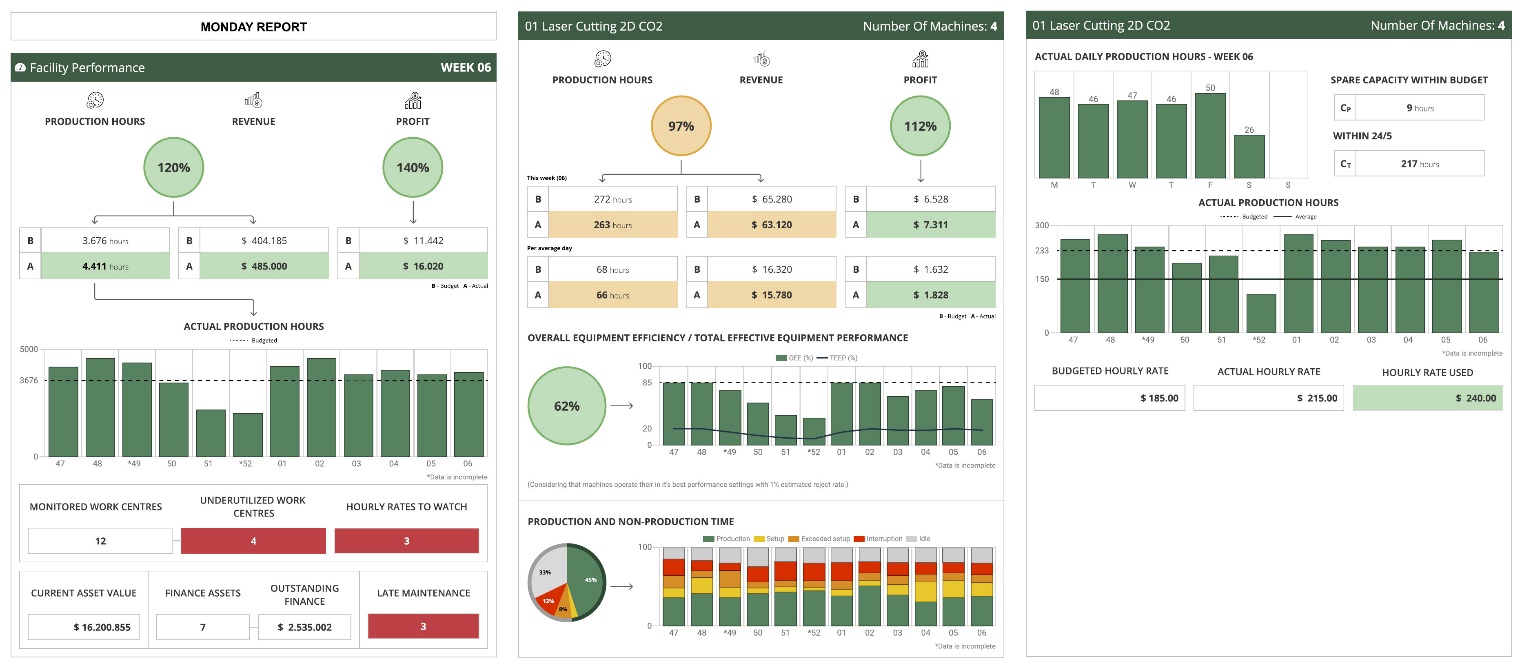

Automatic reporting of critical data

ZOOMFAB has developed a unique automated reporting tool called Monday Report®. Its purpose is to provide easy access to the most critical information on the previous week's factory performance. There is no need to start the computer and remember the password. The report arrives by email right in time for morning coffee. It provides information about the whole facility and individual work centres. A complete form of this report is available on the dashboard, allowing the drilling of the data to any level required.

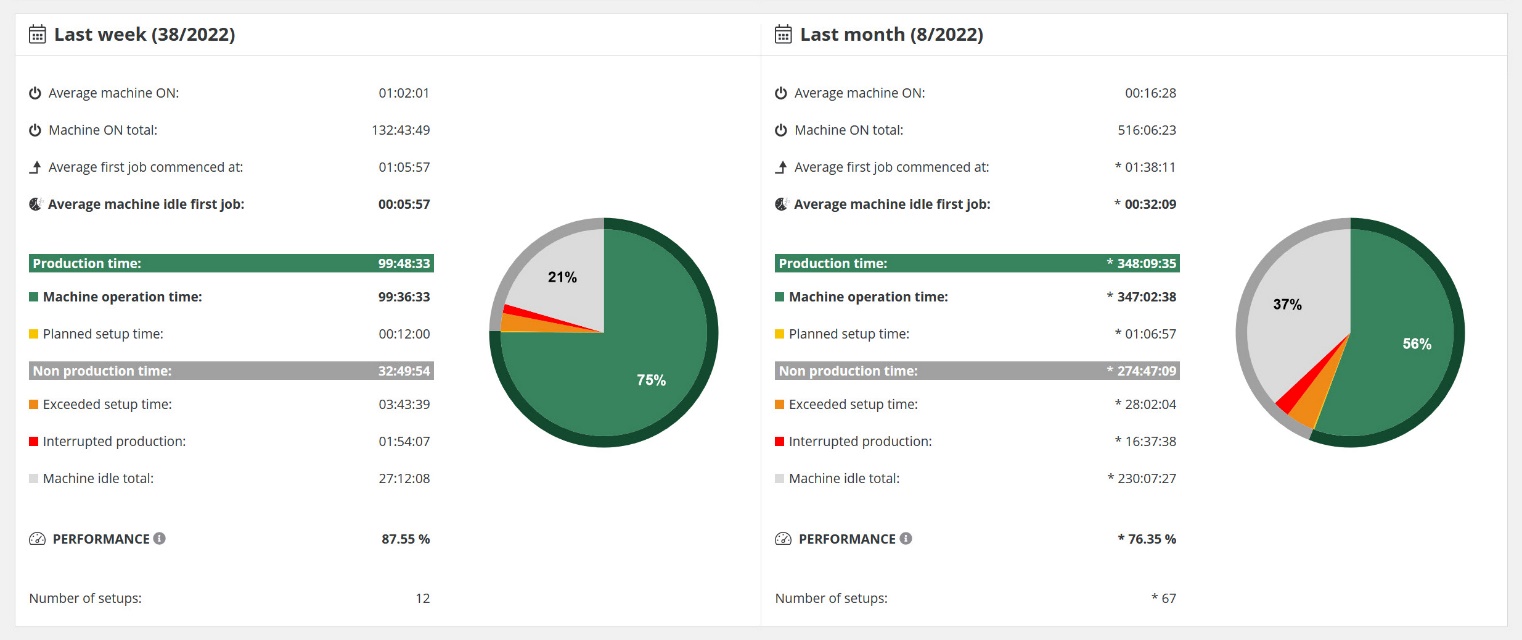

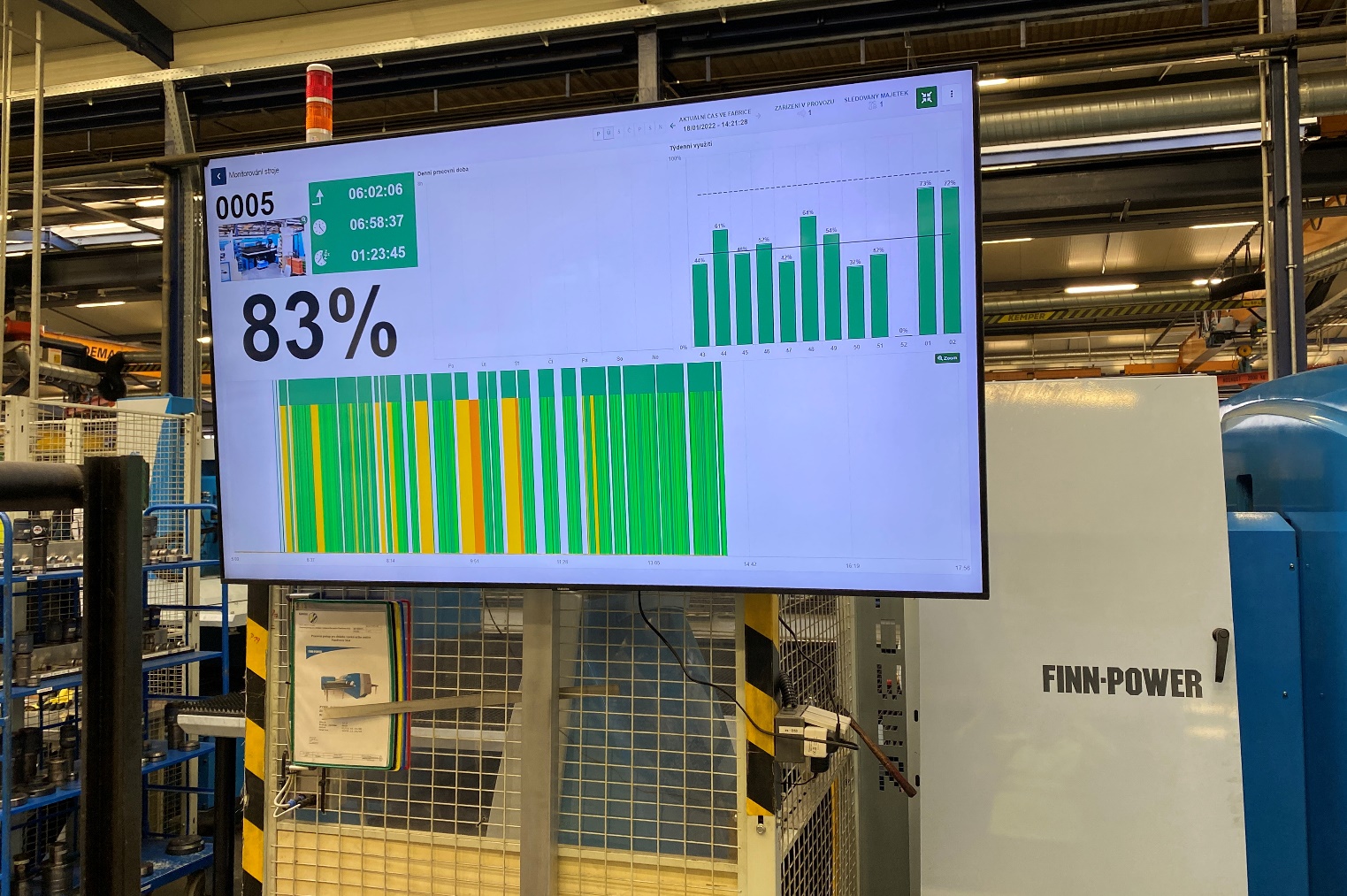

Downtime reduction, pro-active management

Highlighting and tracking downtime is considered one of the most essential KPIs. Reducing downtime is a major goal because downtime means the loss of capacity, disrupted planning, longer lead times, late deliveries and ultimately, the loss of profit. ZOOMFAB provides all the tools a company needs to proactively manage downtime – real-time visibility, alerts and meaningful statistics. You can easily reduce the downtime by 20 to 40% in the first month of ZOOMFAB installation, and reduced downtime instantly converts into an additional capacity.

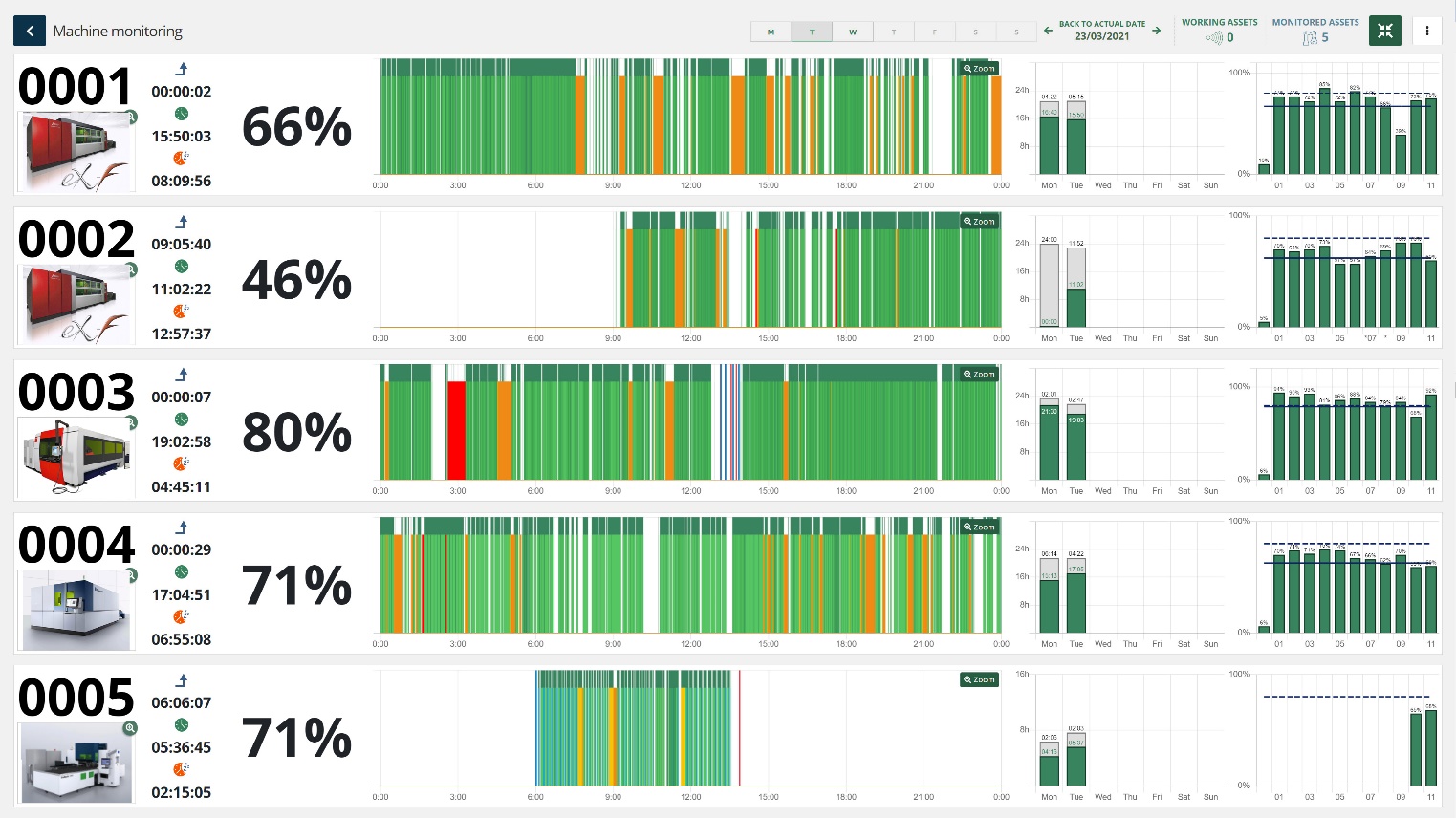

Continuous improvement

For managing improvements, the military uses the "OODA loop". And it works very well in manufacturing too. ZOOMFAB gives you the tools to OBSERVE, ORIENT, DECIDE and ACT, which is the best strategy to make you more productive, competitive and profitable. Watch the trends, look at the data and statistics, simulate the changes, set the goals and implement them. And repeat it for continuous improvement. With ZOOMFAB, you are constantly in control.

Improved communication

It is rare that productivity is a useful means of guiding the improvement activity of the business.

The reason is that there are no practical tools to do so unless you develop your own. And that is a time-consuming task, requires additional resources, bureaucratic work and a lot of meetings with very poor results. ZOOMFAB helps to create an environment that supports productivity. It makes the information relevant to the people doing the work. Giving your people metrics that are related to the work they are doing helps them to see where improvements could be made. Having visibility and operational facts also changes the level of communication, removes suspicion, and encourages employee engagement and contribution.

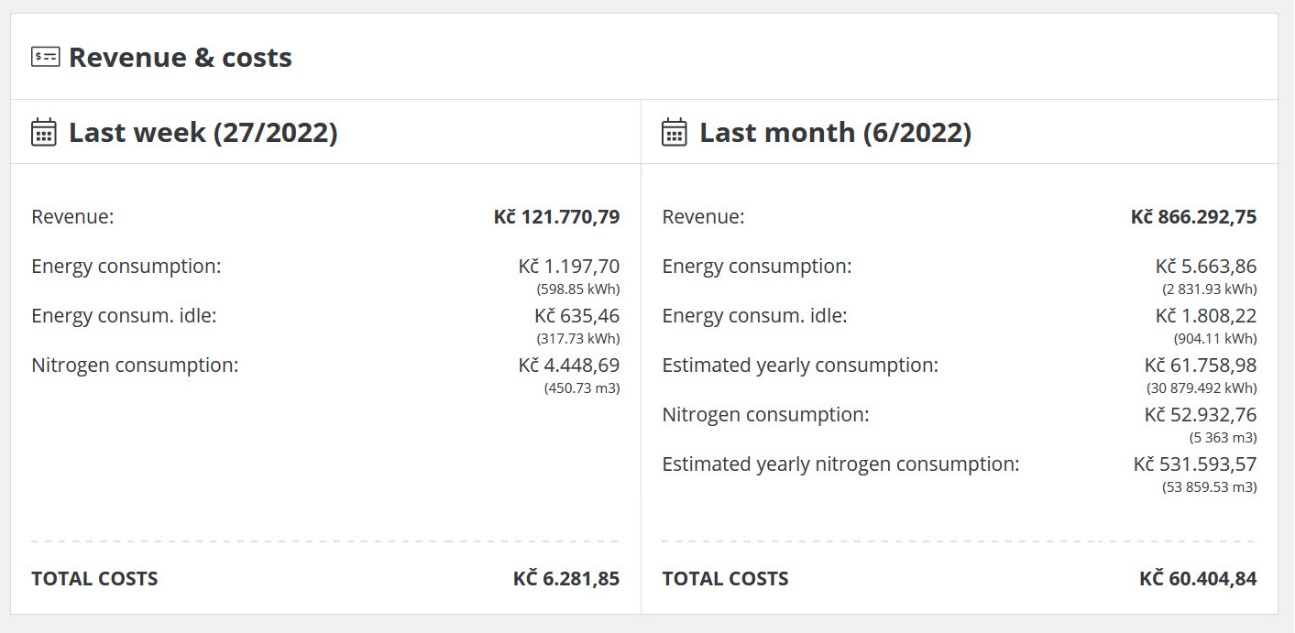

Energy use reduction

As part of monitoring, ZOOMFAB also measures the electricity consumption of each machine. Optionally, monitoring can be expanded to measure laser cutting gases and calculate the use of heating gas used to heat baking ovens. ZOOMFAB's precision energy consumption graphs show you the periods when energy is wasted and calculate the cost so you understand what it means in financial terms. Then, when you decide to purchase a new machine, you can compare it with your existing one, ensuring it is more energy efficient.