IS THE SORTING DEVICE A BOOST FOR YOUR LASER CUTTING MACHINE?

Depending on the material thickness and nesting technique, manual removal of parts from a processed sheet is hard, time-consuming work, often impacting not only the laser machine utilization but also causing production delays. Furthermore, manual sorting requires labor, causes injuries and produces many rejects caused by part separation and removal.

On the other hand, a fully automated sorting system that manages the entire production flow from raw material loading to picking and sorting cut parts allows smooth production flow with minimal human interference. As a result, parts are sorted and ready for the next operation in a planned and predictable manner.

So, the benefits of automated part picking and sorting system attached to your laser are obvious if everything works well. That means the laser machine is not waiting for the sorting device.

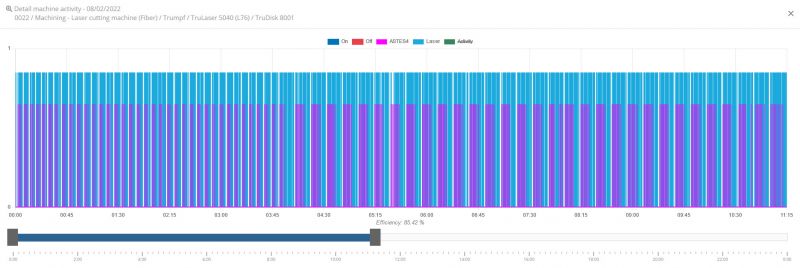

ZOOMFAB monitors various laser cutting machines equipped with automated sorting systems. Below are graphs showing when the sorting device performs well and when it is holding back the laser.

In this example, sorting does not impact laser cutting; everything works at full capacity.

In this example, sorting is very expensive as a million euro laser waits 11 minutes for sorting and sheet loading during each cycle.

The whole system's performance depends very much on the standard of integration between the laser, sorting device and storage system. Another item of significant influence is the NC programming system you use.